SiP Testing

For the functional testing of SiP packages in the consumer electronics industry, we offer a comprehensive solution based on custom instrument boards and software testing platforms, integrated with a Handler system. This significantly enhances the cost-effectiveness of SiP functional testing

ARM+FPGA Controller

Base on Heterogeneous multi-core architecture technology

DMM

Range : 5V

Resolution : 0.00001V

Accuracy : 0.007+0.001

Input Resistance : 10MΩ

Audio Analyzer

Audio ADC channels: 192K SPS, 24 bits, 20 kHz input bandwidth. 2 channel differential input. AC coupled. Input range 2Vrms.THD+N -82dB. LNA channels, Input range ±5V and±50mV

Power Supply

8 x battery output, voltage range 0 to 4.5V with 1mV step, current range -500mA to 650mA

8 x charger supply, voltage range 0 to 7.5V with 5mV step, current range 0 to 500mA@5V

Chip Testing

PCBA Testing

Utilizes self-developed electronic testing modules and software platforms, with customized modular test fixtures based on the product being tested. The test sequences and criteria are configured flexibly according to the test requirements, with the entire process fully automated, ensuring efficient and precise testing and analysis to guarantee the quality of each circuit board

Functional in Circuit Testing

Used for consumer electronics circuit board production lines such as laptops, tablets, and wearable devices. After SMT assembly, high-precision functional testing is conducted, including voltage, current, frequency, etc., to test charging management, audio performance, USB communication etc

DFU Firmware Upgrade Testing

DFU testing equipment is used on PCBA production lines to perform automated firmware flashing, chip programming, system upgrades, and information writing after component assembly. This ensures that the circuit boards have basic functionality or are correctly configured

SoC (System-on-Chip) Testing

The SoC testing equipment is used for functional and performance testing of core chips on PCBA production lines. It collects performance metrics of the chip under various conditions and precisely controls the chip surface temperature to simulate real working environments

Board Testing

Speaker Acoustic Testing

Designed for comprehensive acoustic performance evaluation of consumer electronics and automotive electronic products, including laptops, tablets, smartphones, VR/AR glasses, smartwatches, smart speakers, headphones, etc. Provides various testing methods, including free-field testing, pressure field testing, leakage field testing, and baffle testing, to accurately evaluate the acoustic characteristics of the loudspeakers, helping optimize product design and enhance the end-user experience

Free-Field Testing

Free-field testing is used to simulate acoustic conditions in an open environment to evaluate the performance of a loudspeaker in a space without reflections. This test can measure key performance indicators such as frequency response, total harmonic distortion (THD), sound pressure level, etc., ensuring its sound quality in an ideal environment

Pressure Field Testing

Pressure field testing is used to evaluate the performance of a loudspeaker in a sealed or semi-sealed environment, simulating the interaction between the loudspeaker and the enclosure in actual products. This test can identify acoustic resonances, low-frequency enhancement, or distortion issues that may occur in a closed environment

Leakage Field Testing

Leakage field testing is used to analyze the acoustic performance of a loudspeaker in an environment with air leakage, simulating the influence of minor air leaks on sound quality in real-world usage. This test helps to detect and improve the extent to which sound quality is affected by air leakage

Baffle Testing

Baffle testing simulates reflections and interference in actual usage environments by placing obstacles in front of the loudspeaker to evaluate its acoustic performance in complex environments. This test can help analyze the propagation of sound waves from the loudspeaker in confined spaces and their effects

Speaker Acoustic Testing

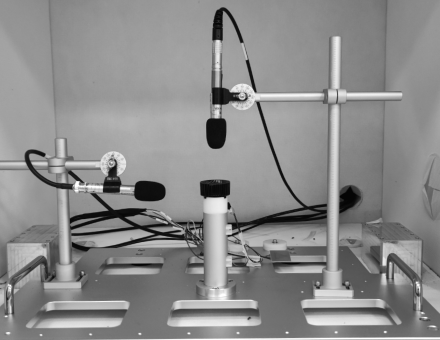

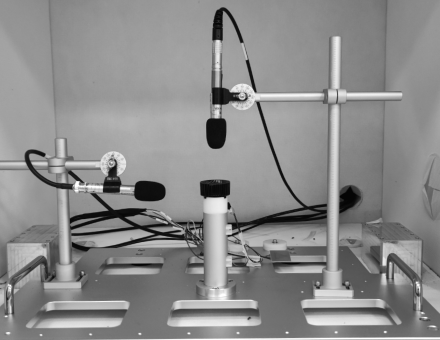

Speaker sound quality testing primarily focuses on evaluating the acoustic performance of individual speakers before assembly. The solution utilizes an in-house developed acoustic testing system, with options to choose between standard or custom high-performance anechoic chambers based on testing needs. It includes modular test fixtures tailored to the specific shape of the speaker being tested. The system is designed to be flexibly configured for automation requirements, ensuring efficient and precise testing and analysis

Basic test parameters include

(FR/THD/HOHD/Phase/Sensitivity/Impedance/F0/Q/Polarity) and Polarity

Enclosure Acoustic Isolation Performance

>40dB

Operation Mode

Manual/Automated Design

Safety Protection

?Equipped with Safety Light Curtains

Operating Voltage

110~220V 50Hz

Microphone Acoustic Testing

In the consumer electronics and automotive industries, analog microphones and digital microphones are critical components for achieving high-quality audio input. With the increasing diversity of device functions and user demands for audio quality, the performance testing of microphones has become particularly important. Our testing solutions are designed for different types of microphone products, such as Mic modules, MLB Mics (mainboard microphones), Flex Mics (flexible circuit microphones), and are applied to products including but not limited to laptops, tablets, smartphones, VR/AR glasses, smartwatches, smart speakers, headphones, and automotive microphones

Free-Field Testing

This test is conducted in an anechoic chamber, where a standard sound source emits sound waves from different directions around the microphone. The output signal of the microphone is measured to assess its acoustic performance in a reflection-free free-field, primarily measuring frequency response, sensitivity, and signal-to-noise ratio

Pressure Field Testing

The microphone is placed in a sealed or semi-sealed chamber, and sound waves of different frequencies are applied through a sound source to measure the microphone’s output characteristics in this pressure environment. This test evaluates the microphone’s acoustic performance in a sealed or semi-sealed environment, assessing its performance in the actual usage environment within a device

Directivity Testing

In an anechoic chamber, the microphone or microphone array is rotated to test its sound pressure level (SPL) and frequency response at different angles, measuring the microphone’s response to sound waves from different directions, particularly focusing on the directional characteristics of microphone arrays and multi-microphone systems

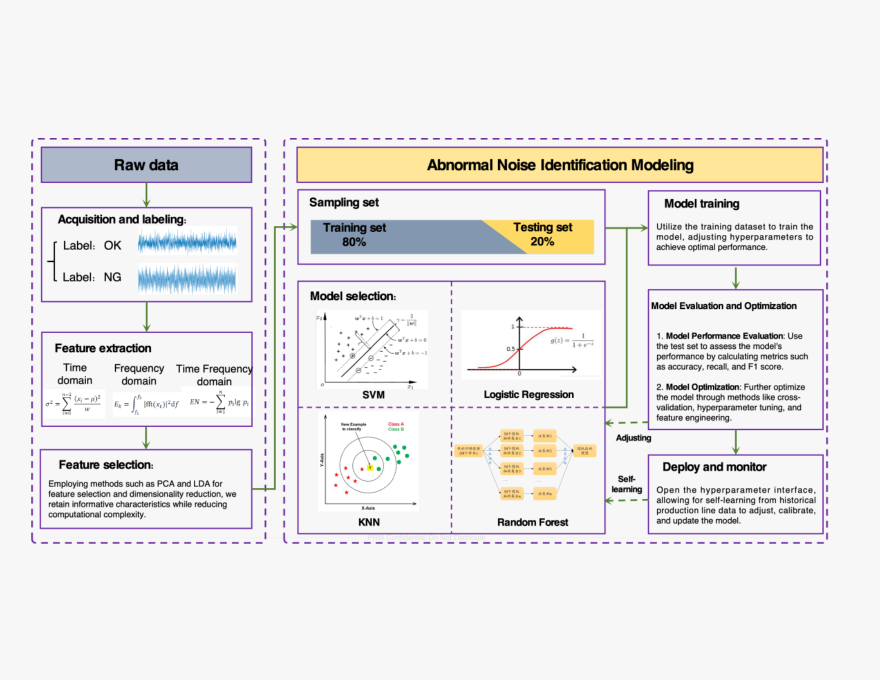

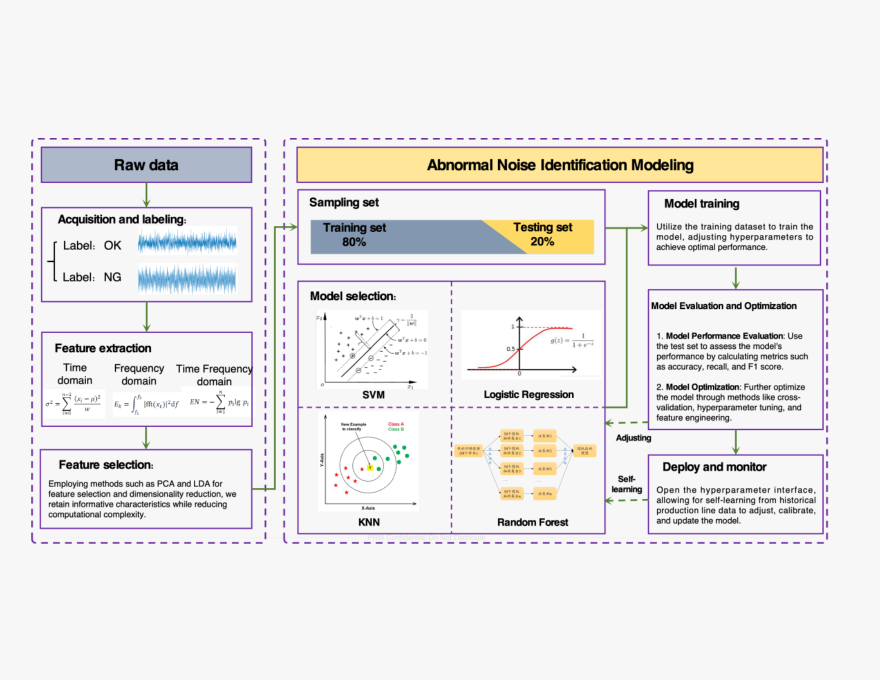

Fan Abnormal Noise Testing

Fan noise detection is a testing technology used to identify and analyze abnormal noises generated by fans during operation. Such noises are often caused by issues like poor assembly of fan components, material wear, imbalance, or external interference. This detection is crucial in fan manufacturing, quality control, and product development because abnormal noises can affect the user experience and may signal potential mechanical failures or performance degradation

Abnormal Sound Identification

Utilizing high-sensitivity microphones or vibration sensors to capture the sound signals of the fan under various operating conditions. By analyzing the frequency spectrum and time-domain characteristics of the sound signals, abnormal audio signals different from normal operating conditions are identified

Noise Localization

Using acoustic imaging or vibration analysis techniques to determine the specific source of the abnormal sound, such as bearings, blades, or motor components. This helps to rapidly diagnose potential issues with the fan and take appropriate corrective measures

Quality Assessment

Based on the test results, evaluating the overall operational quality of the fan to determine whether it complies with design and manufacturing standards. This provides data support for product improvement and optimization

Vibration&Noise Tesing of Vibrators

The vibration motor module performance and noise test system is used to evaluate the performance and noise characteristics of the vibration motor module during operation. Vibration motors are widely used in consumer electronic products such as mobile devices, wearable devices, and game controllers to provide haptic feedback and vibration alerts. This testing system plays a crucial role in the research, production, and quality control of vibration motor modules, ensuring product stability, consistent performance, and user experience during usage

Acoustic Module

Vibration Module

Smart Speaker Acoustic Testing

The system is primarily designed for the acoustic performance evaluation of smart speakers. It requires simultaneous assessment of both the speaker and microphone acoustic performance. The solution can utilize a self-developed acoustic testing system, with the option to select or customize high-performance soundproofing box solutions based on testing needs, and tailor testing fixtures according to the specific products being tested. Depending on the testing requirements, automation needs can be flexibly configured to achieve efficient and high-precision testing and analysis

Speaker Test

By testing the frequency response, distortion, sensitivity, and other parameters of the speaker, we evaluate its sound output capability at different frequencies, ensuring that the speaker can accurately reproduce sound across various frequency bands

Microphone Test

By assessing the frequency response, distortion, sensitivity, and other parameters of the microphone array, we evaluate the collection capabilities of each microphone, ensuring that the smart speaker performs well in voice recognition

AR/VR Acoustic Testing

With the rapid development of Augmented Reality (AR) and Virtual Reality (VR) technologies, acoustic testing of AR/VR devices is crucial to provide immersive, high-quality audio experiences. Our acoustic testing solutions are designed to meet the unique requirements of AR/VR headsets and other consumer electronic devices, ensuring optimal audio performance in various usage scenarios

Action Cameras Acoustic Testing

Action cameras are widely used in extreme sports, outdoor adventures, travel documentation, and other scenarios. The acoustic performance of their microphones and speakers is crucial for capturing and playing clear, natural audio. As action cameras are often used in noisy, windy, or underwater environments, acoustic performance testing should not only consider normal operating conditions but also simulate various extreme environments to ensure that the microphones and speakers perform optimally in all situations

Laptop Acoustic Testing

To ensure that the audio quality of laptops meets the expected standards, we provide a comprehensive set of acoustic testing solutions that cover both the semi-finished and finished stages. This includes semi-finished stage microphone acoustic testing for the screen, as well as microphone sealing tests. Additionally, we offer finished product speaker/microphone acoustic testing and microphone sealing tests

Frequency Response Testing

Tests the microphone’s sensitivity across the entire frequency range to ensure it can capture clear sound

Sensitivity Testing

Testing the output signal strength of the microphone to ensure it accurately reflects the intensity of the input sound

Distortion Testing

Testing the microphone’s nonlinear distortion at different sound pressure levels to ensure recording clarity

Seal Testing

Testing the product during the assembly process or after the complete assembly of the whole machine, using frequency response testing to determine if there are any gaps in the assembly process that may cause sound leakage

Loopback Testing

Used to evaluate the overall performance and quality of the built-in audio system in a laptop, including the microphone, speaker, and sound card

TWS Earphone Acoustic Testing

This is suitable for conducting acoustic performance tests on TWS (True Wireless Stereo) Bluetooth earphone. Depending on the testing requirements, a standard or custom high-performance acoustic chamber can be selected, and test fixtures can be customized. Automated testing needs can be flexibly configured according to testing requirements, enabling efficient and precise testing and analysis

Smartphone Acoustic Testing

Testing the acoustic performance of mobile phones is a critical step in ensuring product quality. Through acoustic testing on the production line, the performance of audio components such as speakers and microphones can be rapidly and efficiently detected, ensuring that the sound quality of each device meets the standard. Common testing items include frequency response, total harmonic distortion (THD), and Rub & Buzz abnormal noise detection

SiP Testing

For the functional testing of SiP packages in the consumer electronics industry, we offer a comprehensive solution based on custom instrument boards and software testing platforms, integrated with a Handler system. This significantly enhances the cost-effectiveness of SiP functional testing

ARM+FPGA Controller

Base on Heterogeneous multi-core architecture technology

DMM

Range : 5V

Resolution : 0.00001V

Accuracy : 0.007+0.001

Input Resistance : 10MΩ

Audio Analyzer

Audio ADC channels: 192K SPS, 24 bits, 20 kHz input bandwidth. 2 channel differential input. AC coupled. Input range 2Vrms.THD+N -82dB. LNA channels, Input range ±5V and±50mV

Power Supply

8 x battery output, voltage range 0 to 4.5V with 1mV step, current range -500mA to 650mA

8 x charger supply, voltage range 0 to 7.5V with 5mV step, current range 0 to 500mA@5V

PCBA Testing

Utilizes self-developed electronic testing modules and software platforms, with customized modular test fixtures based on the product being tested. The test sequences and criteria are configured flexibly according to the test requirements, with the entire process fully automated, ensuring efficient and precise testing and analysis to guarantee the quality of each circuit board

Functional in Circuit Testing

Used for consumer electronics circuit board production lines such as laptops, tablets, and wearable devices. After SMT assembly, high-precision functional testing is conducted, including voltage, current, frequency, etc., to test charging management, audio performance, USB communication etc

DFU Firmware Upgrade Testing

DFU testing equipment is used on PCBA production lines to perform automated firmware flashing, chip programming, system upgrades, and information writing after component assembly. This ensures that the circuit boards have basic functionality or are correctly configured

SoC (System-on-Chip) Testing

The SoC testing equipment is used for functional and performance testing of core chips on PCBA production lines. It collects performance metrics of the chip under various conditions and precisely controls the chip surface temperature to simulate real working environments

Speaker Acoustic Testing

Acoustic Module

Vibration Module

Speaker Acoustic Testing

Designed for comprehensive acoustic performance evaluation of consumer electronics and automotive electronic products, including laptops, tablets, smartphones, VR/AR glasses, smartwatches, smart speakers, headphones, etc. Provides various testing methods, including free-field testing, pressure field testing, leakage field testing, and baffle testing, to accurately evaluate the acoustic characteristics of the loudspeakers, helping optimize product design and enhance the end-user experience

Free-Field Testing

Free-field testing is used to simulate acoustic conditions in an open environment to evaluate the performance of a loudspeaker in a space without reflections. This test can measure key performance indicators such as frequency response, total harmonic distortion (THD), sound pressure level, etc., ensuring its sound quality in an ideal environment

Pressure Field Testing

Pressure field testing is used to evaluate the performance of a loudspeaker in a sealed or semi-sealed environment, simulating the interaction between the loudspeaker and the enclosure in actual products. This test can identify acoustic resonances, low-frequency enhancement, or distortion issues that may occur in a closed environment

Leakage Field Testing

Leakage field testing is used to analyze the acoustic performance of a loudspeaker in an environment with air leakage, simulating the influence of minor air leaks on sound quality in real-world usage. This test helps to detect and improve the extent to which sound quality is affected by air leakage

Baffle Testing

Baffle testing simulates reflections and interference in actual usage environments by placing obstacles in front of the loudspeaker to evaluate its acoustic performance in complex environments. This test can help analyze the propagation of sound waves from the loudspeaker in confined spaces and their effects

Speaker Acoustic Testing

Speaker sound quality testing primarily focuses on evaluating the acoustic performance of individual speakers before assembly. The solution utilizes an in-house developed acoustic testing system, with options to choose between standard or custom high-performance anechoic chambers based on testing needs. It includes modular test fixtures tailored to the specific shape of the speaker being tested. The system is designed to be flexibly configured for automation requirements, ensuring efficient and precise testing and analysis

Basic test parameters include

(FR/THD/HOHD/Phase/Sensitivity/Impedance/F0/Q/Polarity) and Polarity

Enclosure Acoustic Isolation Performance

>40dB

Operation Mode

Manual/Automated Design

Safety Protection

?Equipped with Safety Light Curtains

Operating Voltage

110~220V 50Hz

Microphone Acoustic Testing

In the consumer electronics and automotive industries, analog microphones and digital microphones are critical components for achieving high-quality audio input. With the increasing diversity of device functions and user demands for audio quality, the performance testing of microphones has become particularly important. Our testing solutions are designed for different types of microphone products, such as Mic modules, MLB Mics (mainboard microphones), Flex Mics (flexible circuit microphones), and are applied to products including but not limited to laptops, tablets, smartphones, VR/AR glasses, smartwatches, smart speakers, headphones, and automotive microphones

Free-Field Testing

This test is conducted in an anechoic chamber, where a standard sound source emits sound waves from different directions around the microphone. The output signal of the microphone is measured to assess its acoustic performance in a reflection-free free-field, primarily measuring frequency response, sensitivity, and signal-to-noise ratio

Pressure Field Testing

The microphone is placed in a sealed or semi-sealed chamber, and sound waves of different frequencies are applied through a sound source to measure the microphone’s output characteristics in this pressure environment. This test evaluates the microphone’s acoustic performance in a sealed or semi-sealed environment, assessing its performance in the actual usage environment within a device

Directivity Testing

In an anechoic chamber, the microphone or microphone array is rotated to test its sound pressure level (SPL) and frequency response at different angles, measuring the microphone’s response to sound waves from different directions, particularly focusing on the directional characteristics of microphone arrays and multi-microphone systems

Fan Abnormal Noise Testing

Fan noise detection is a testing technology used to identify and analyze abnormal noises generated by fans during operation. Such noises are often caused by issues like poor assembly of fan components, material wear, imbalance, or external interference. This detection is crucial in fan manufacturing, quality control, and product development because abnormal noises can affect the user experience and may signal potential mechanical failures or performance degradation

Abnormal Sound Identification

Utilizing high-sensitivity microphones or vibration sensors to capture the sound signals of the fan under various operating conditions. By analyzing the frequency spectrum and time-domain characteristics of the sound signals, abnormal audio signals different from normal operating conditions are identified

Noise Localization

Using acoustic imaging or vibration analysis techniques to determine the specific source of the abnormal sound, such as bearings, blades, or motor components. This helps to rapidly diagnose potential issues with the fan and take appropriate corrective measures

Quality Assessment

Based on the test results, evaluating the overall operational quality of the fan to determine whether it complies with design and manufacturing standards. This provides data support for product improvement and optimization

Vibration&Noise Tesing of Vibrators

The vibration motor module performance and noise test system is used to evaluate the performance and noise characteristics of the vibration motor module during operation. Vibration motors are widely used in consumer electronic products such as mobile devices, wearable devices, and game controllers to provide haptic feedback and vibration alerts. This testing system plays a crucial role in the research, production, and quality control of vibration motor modules, ensuring product stability, consistent performance, and user experience during usage

Smart Speaker Testing Solutions

Smart Speaker Acoustic Testing

The system is primarily designed for the acoustic performance evaluation of smart speakers. It requires simultaneous assessment of both the speaker and microphone acoustic performance. The solution can utilize a self-developed acoustic testing system, with the option to select or customize high-performance soundproofing box solutions based on testing needs, and tailor testing fixtures according to the specific products being tested. Depending on the testing requirements, automation needs can be flexibly configured to achieve efficient and high-precision testing and analysis

Speaker Test

By testing the frequency response, distortion, sensitivity, and other parameters of the speaker, we evaluate its sound output capability at different frequencies, ensuring that the speaker can accurately reproduce sound across various frequency bands

Microphone Test

By assessing the frequency response, distortion, sensitivity, and other parameters of the microphone array, we evaluate the collection capabilities of each microphone, ensuring that the smart speaker performs well in voice recognition

AR/VR Acoustic Testing

With the rapid development of Augmented Reality (AR) and Virtual Reality (VR) technologies, acoustic testing of AR/VR devices is crucial to provide immersive, high-quality audio experiences. Our acoustic testing solutions are designed to meet the unique requirements of AR/VR headsets and other consumer electronic devices, ensuring optimal audio performance in various usage scenarios

Action Cameras Acoustic Testing

Action cameras are widely used in extreme sports, outdoor adventures, travel documentation, and other scenarios. The acoustic performance of their microphones and speakers is crucial for capturing and playing clear, natural audio. As action cameras are often used in noisy, windy, or underwater environments, acoustic performance testing should not only consider normal operating conditions but also simulate various extreme environments to ensure that the microphones and speakers perform optimally in all situations

Laptop Acoustic Testing

To ensure that the audio quality of laptops meets the expected standards, we provide a comprehensive set of acoustic testing solutions that cover both the semi-finished and finished stages. This includes semi-finished stage microphone acoustic testing for the screen, as well as microphone sealing tests. Additionally, we offer finished product speaker/microphone acoustic testing and microphone sealing tests

Frequency Response Testing

Tests the microphone’s sensitivity across the entire frequency range to ensure it can capture clear sound

Sensitivity Testing

Testing the output signal strength of the microphone to ensure it accurately reflects the intensity of the input sound

Distortion Testing

Testing the microphone’s nonlinear distortion at different sound pressure levels to ensure recording clarity

Seal Testing

Testing the product during the assembly process or after the complete assembly of the whole machine, using frequency response testing to determine if there are any gaps in the assembly process that may cause sound leakage

Loopback Testing

Used to evaluate the overall performance and quality of the built-in audio system in a laptop, including the microphone, speaker, and sound card

TWS Earphone Acoustic Testing

This is suitable for conducting acoustic performance tests on TWS (True Wireless Stereo) Bluetooth earphone. Depending on the testing requirements, a standard or custom high-performance acoustic chamber can be selected, and test fixtures can be customized. Automated testing needs can be flexibly configured according to testing requirements, enabling efficient and precise testing and analysis

Smartphone Acoustic Testing

Testing the acoustic performance of mobile phones is a critical step in ensuring product quality. Through acoustic testing on the production line, the performance of audio components such as speakers and microphones can be rapidly and efficiently detected, ensuring that the sound quality of each device meets the standard. Common testing items include frequency response, total harmonic distortion (THD), and Rub & Buzz abnormal noise detection